Filtration System rau Melt Polymer pom

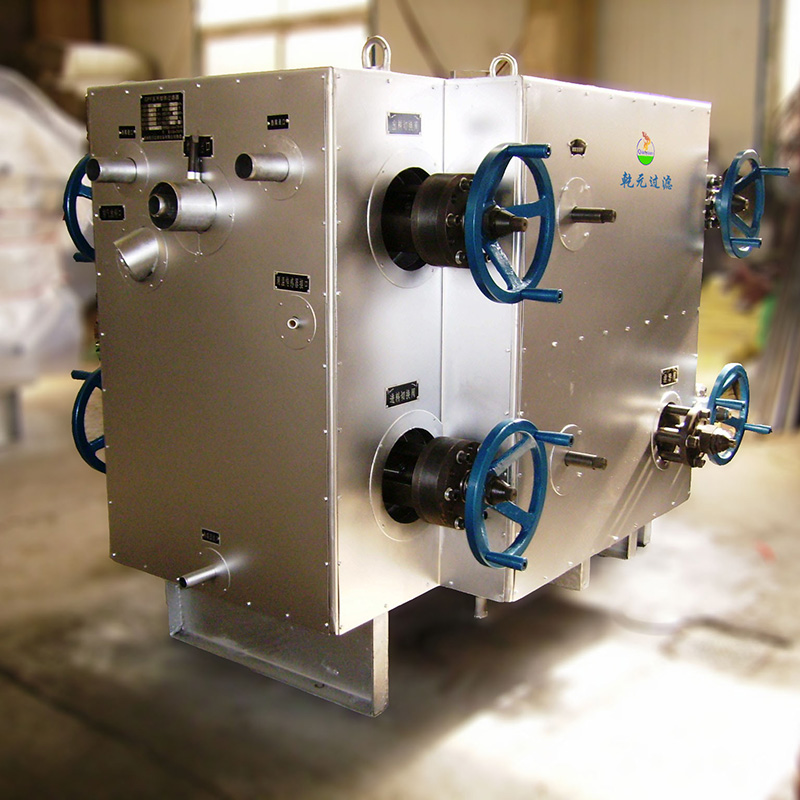

Melt Polymer Filtration System

Lub tshuab ziab khaub ncaws polymer yog qhov tseem ceeb hauv ntau daim ntawv thov uas polymers tau ua tiav lossis siv, xws li hauv kev tsim khoom ntawm PET / PA / PP polymer kev lag luam, pre-polymerizaton, kawg polymerization, filament yarn, polyester staple fiber spinning, BOPET / BOPP films , los yog daim nyias nyias.Cov txheej txheem no pab tshem tawm impurities, kab mob, thiab viscosity-cuam tshuam hais los ntawm molten polymer, kom ntseeg tau qhov zoo thiab sib xws ntawm cov khoom kawg.

Txhawm rau txhim kho qhov zoo ntawm cov yaj polymer thiab ua kom lub neej ua haujlwm ntev ntawm cov khoom sib txuas, ib qho txuas txuas ntxiv (CPF) yog ntsia rau ntawm cov yeeb nkab tseem ceeb.Nws muaj peev xwm tshem tawm txhua yam impurities hais nrog ib txoj kab uas hla ntau tshaj 20-15μm nyob rau hauv lub yaj, thiab kuj muaj nuj nqi ntawm homogenizing lub yaj.Feem ntau lub lim dej muaj ob chav lim, thiab peb-txoj kev li qub tau txuas nrog lub raj xa dej.Peb-txoj kev li qub tuaj yeem hloov pauv mus ib ntus kom hloov pauv kev siv cov lim dej kom ntseeg tau qhov pom tsis tu ncua.Lub tsev ntawm lub lim chamber yog cam khwb cia rau hauv ib thooj nrog stainless hlau.Qhov loj-thaj chaw lim yog tsim los ntawm ntau yam pleated tswm ciab lim ntsiab.Lub tog raj kheej lim yog txhawb nqa los ntawm cov tub ntxhais lub tog raj kheej nrog qhov, thiab txheej txheej yog nruab nrog ib leeg lossis ntau txheej hlau mesh lossis sintered hlau hmoov disc lossis ntau txheej hlau mesh & sintered fiber ntau lossis sintered hlau hlau mesh, thiab lwm yam. . nyob rau hauv sib txawv pom tus nqi uas yog raws li qhov yuav tsum tau ntawm cov khoom kawg.

Feem ntau muaj ntau hom kev pom, xws li Kab rov tav nruam pom qhov system, ntsug nruam pom qhov system.Piv txwv li, thaum lub sij hawm PET chips spinning txheej txheem, ntsug tswm ciab-hom lim hom yog feem ntau thov, uas yog nrog ib tug pom cheeb tsam ntawm 0.5㎡ ib tug tswm ciab tub ntxhais.Feem ntau siv cov kev teeb tsa ntawm 2, 3, lossis 4 tswm ciab cores, sib haum rau qhov chaw pom ntawm 1, 1.5, lossis 2㎡, thiab cov khoom sib xyaw ua kom pom muaj peev xwm yog 150, 225, 300 kg / h.Txoj kab ntsug ntsug muaj qhov loj dua thiab ua haujlwm nyuaj, tab sis nws muaj ntau yam zoo los ntawm cov txheej txheem kev pom: (1) Nws muaj peev xwm thermal loj, me me yaj qhov kub hloov pauv, thiab tsis muaj qhov chaw tuag thaum cov khoom ntws.(2) Lub rwb thaiv tsev lub tsho qauv tsim nyog, thiab qhov kub thiab txias tsis sib xws.(3) Nws yog qhov yooj yim los nqa cov tub ntxhais lim thaum hloov lub lim.

Lub siab sib txawv ua ntej thiab tom qab lub lim siv tshiab yog tsawg.Raws li lub sij hawm siv nce, cov lim nruab nrab qhov maj mam ua thaiv.Thaum lub siab sib txawv mus txog qhov teeb tsa tus nqi, piv txwv li, rau PET chips spinning, feem ntau cov duab yog li 5-7MPa, lub lim chamber yuav tsum tau hloov.Thaum qhov kev tso cai siab sib txawv dhau lawm, lub lim mesh tuaj yeem sib tw, qhov mesh loj tuaj, thiab qhov pom tseeb txo kom txog thaum lub lim nruab nrab ruptured.Lub tshuab lim hloov pauv yuav tsum tau muab ntxuav ua ntej rov siv dua.Qhov pom tseeb ntawm cov nyhuv yog qhov zoo tshaj plaws txiav txim siab los ntawm qhov kev sim "npuas" kev sim, tab sis nws kuj tuaj yeem txiav txim siab raws li qhov sib txawv ntawm lub siab ua ntej thiab tom qab lub lim hloov tshiab.Feem ntau, thaum lub tswm ciab lim tau tawg lossis ntxuav 10-20 zaug, nws yuav tsum tsis txhob siv ntxiv lawm.

Piv txwv li, rau Barmag NSF series lim, lawv tau rhuab los ntawm Biphenyl chav nyob rau hauv lub tsho, tab sis qhov kub ntawm lub tshav kub hloov kua dej yuav tsum tsis txhob ntau tshaj 319 ℃, thiab lub siab tshaj plaws Biphenyl chav siab yog 0.25MPa.Qhov siab tshaj plaws tsim siab ntawm lub lim chamber yog 25MPa.Qhov siab tshaj plaws tso cai sib txawv ua ntej thiab tom qab lub lim yog 10MPa.

Technical Parameters

| Qauv | L | B | H | H1 | H2 | FIX (H3) | Inlet & qhov hluav taws xob DN (Φ /) | Lim cheeb tsam (m2) | Siv tau Screw Bar (Φ /) | Tsim tus nqi ntws (kg / h) | Lim Tsev | Lim Element | Qhov hnyav tag nrho (kg) |

| PF2T-0.5B | 900 | 1050 | 1350 | Raws li tus neeg siv khoom Site | 2200 | 22 | 2 x0,5 | 65 | 40-80 : kuv | ib 158x565 | 35x425x 4 | 660 | |

| PF2T-1.05B | 900 | 1050 | 1350 | 2200 | 30 | 2 x1,05 | 90 | 100-180 | Φ172x600 | 35x425x 7 | 690 ib | ||

| PF2T-1.26B | 900 | 1050 | 1390 ib | 2240 | 30 | 2 x1,26 | 105 | 150-220 : kuv | ib 178x640 | 35x485x 7 | 770 ib | ||

| PF2T-1.8B | 950 ua | 1140 | 1390 ib | 2240 | 40 | 2 x1,8 | 120 | 220-320 : kuv | wb 235x620 | Φ35x425x12 | 980 ua | ||

| PF2T-1.95B | 950 ua | 1140 | 1390 ib | 2240 | 40 | 2 x1,95 | 130 | 250-350 | wb 235x620 | 35x425x13 | 990 ua | ||

| PF2T-2.34B | 1030 | 1200 | 1430 ib | 23 30 | 40 | 2 x 34 | 135 | 330-420 : kuv | wb 235x690 | 35x485x13 | 1290 | ||

| PF2T-2.7B | 1150 | 1200 | 1440 | 2350 | 50 | 2 x2.7 | 150 | 400-500 | Φ260x690 | Φ35x485x15 | 1320 | ||

| PF2T-3.5B | 1150 | 1250 | 1440 | 2350 | 50 | 2 x3,5 | 160 | 500-650 | ib 285x695 | 35x485x19 | 1450 | ||

| PF2T-4.0B | 1150 | 1250 | 1500 | 2400 | 50 | 2 x4.0 | 170 | 600-750 | 285x735 ua | 35x525x19 | 1500 | ||

| PF2T-4.5B | 1150 | 1250 | 1550 | 2400 | 50 | 2 x4,5 | 180 | 650-900 Nws | wb 285x785 | 35x575x19 | 1550 | ||

| PF2T-5.5B | 1200 | 1300 | 1500 | 2350 | 50 | 2 x5,5 | 190 | 800-1000 | 350x755 ua | Φ50x500x15 | 1650 | ||