Melt Polymer Candle Lim rau High Viscosity Substances Lim

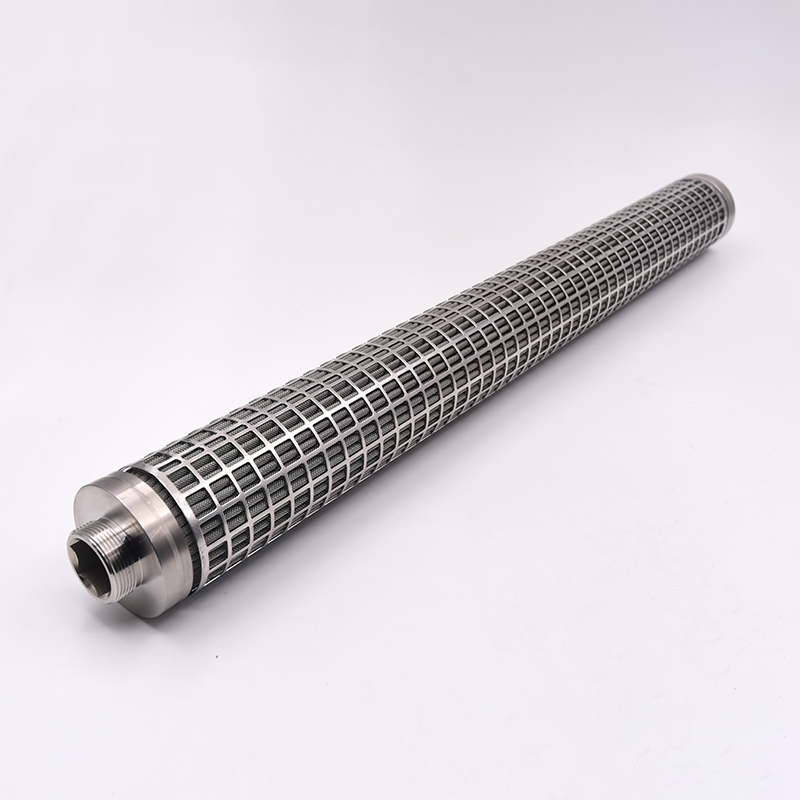

Melt Polymer Candle Filter

Melt filter element yog tag nrho cov hlau lim welded los ntawm argon arc vuam.Cov txheej lim tau txais cov txheej txheem ntau-pleat folding txheej txheem, nrog rau cov pore loj faib thiab nce qhov chaw lim.Cov hlau pleated lim yog ua los ntawm stainless hlau, tsis muaj to los yog nruab nrab shedding.Nyob rau hauv ib puag ncig kev kub siab, stainless hlau pleated lim txais ib lub pob txha tsim.Cov pob txha sab hauv thiab sab nrauv zoo heev txhim kho lub siab ua haujlwm ntawm cov hlau pleated lim caij.Lub ntsiab lim txheej ntawm Pleated Filter tsuas yog siv ob yam ntaub ntawv: stainless hlau xaim mesh thiab stainless hlau Sintered fiber.Stainless hlau hlau mesh yog woven los ntawm stainless hlau xaim.Nws cov pleated lim muaj cov yam ntxwv ntawm cov pores du, yooj yim tu, kub tsis kam, corrosion kuj, tsis muaj hlau mesh ntog tawm, thiab ntev filtration voj voog.Stainless hlau sintered fiber ntau yog ib tug ntxeem tau sib sib zog nqus lim khoom ua los ntawm stainless hlau fibers sintered ntawm kub.Nws cov pleated lim muaj cov yam ntxwv ntawm siab porosity, zoo huab cua permeability, muaj zog av tuav, thiab muaj zog regeneration muaj peev xwm.

Melt filter element yog cov khoom siv pom dav siv hauv kev lag luam tshuaj fiber ntau rau polymer yaj thiab lwm yam khoom muaj viscosity.Nws txoj haujlwm yog tshem tawm cov khoom tsis huv xws li carbonized hais thiab hlau oxides hauv cov yaj, txhim kho cov purity ntawm cov yaj, muab cov khoom tsim nyog rau cov txheej txheem hauv qab, thiab xyuas kom muaj kev ua haujlwm zoo ntawm cov lim dej.

Cov yam ntxwv

1. Resistant mus rau kub kub, siab siab thiab tshuaj corrosion.

2. Kev ua pa zoo heev, cov av loj tuav lub peev xwm, lub zog siab, kev sib khi zoo, lub neej ntev, thiab tuaj yeem ntxuav thiab rov qab siv dua.

3. Qhov chaw lim folded yog 3-5 npaug ntawm hom cylindrical.

4. Ua haujlwm kub: -60-500 ℃.

5. Qhov siab tshaj plaws qhov sib txawv ntawm cov khoom lim tuaj yeem tiv taus: 10MPa.

Yam Khoom Siv Daim Ntawv Thov Parameter

1. Ua haujlwm siab: 30Mpa.

2. Ua haujlwm kub: 300 ℃.

3. Cov av tuav muaj peev xwm: 16.9 ~ 41mg / cm².

Txoj kev sib txuas khoom

Standard interface (xws li 222, 220, 226) ceev interface kev twb kev txuas, threaded kev twb kev txuas, flange kev twb kev txuas, khi pas nrig txuas, tshwj xeeb customized interface.

Cov cheeb tsam thov

1. Petrochemical: Refining, chemical ntau lawm thiab kev sib cais thiab rov qab cov khoom nruab nrab.

2. Metallurgy: siv rau kev pom ntawm hydraulic systems ntawm dov mills thiab nruam casting tshuab.

3. Textile: Purification thiab uniform filtration ntawm polyester yaj thaum lub sij hawm daim duab txheej txheem.

4. Cov khoom siv hluav taws xob thiab cov chaw muag tshuaj: kev kho ua ntej thiab pom cov dej thim rov qab osmosis thiab dej deionized, kev kho ua ntej thiab pom kev ntxuav cov kua dej thiab cov piam thaj.

5. Thermal fais fab thiab nuclear fais fab: purification ntawm lubrication systems, ceev tswj systems, bypass tswj systems ntawm roj turbines thiab boilers, purification ntawm dej twj tso kua mis, kiv cua thiab plua plav tshem tawm systems.

Ntau Yam Khoom