Lub molten PET PA PP siab polymer yuav tsum tau lim ua ntej cov tshuaj fiber ntau spinning kom tshem tawm cov impurity thiab gel hais entrained nyob rau hauv lub yaj los tiv thaiv lub plugging ntawm lub spinneret qhov;Thaum cov yaj polymer ntws los ntawm cov txheej txheem spin pack, tiv thaiv tau tsim, kom cov yaj Friction generates tshav kub, kub nce, thiab rheological zog ntawm cov yaj yog zoo dua.Nyob rau tib lub sij hawm, lub yaj yog tag nrho tov los tiv thaiv viscosity sib txawv ntawm cov melts;cov yaj yog sib npaug rau txhua qhov me me ntawm spinneret;Nrog rau qhov nce ntawm lub sij hawm siv ntawm spin pack lim, impurities nyob rau hauv lub mesh pob lim txheej yuav nce, thiab lub siab ntawm lub rooj sib txoos yuav maj mam nce.Lub siab nce ceev yog ceev, thiab lub neej kev pab cuam ntawm lub rooj sib txoos yog luv.Thaum lub rooj sib txoos nce mus rau qee qhov siab, nws yog ib qho tsim nyog los hloov lub rooj sib txoos hauv lub sijhawm, txwv tsis pub, lub twj tso kua mis ntsuas yog crushed, los yog spinneret yog deformed, los yog leakage tshwm sim.

Lub molten PET PA PP siab polymer yuav tsum tau lim ua ntej cov tshuaj fiber ntau spinning kom tshem tawm cov impurity thiab gel hais entrained nyob rau hauv lub yaj los tiv thaiv lub plugging ntawm lub spinneret qhov;Thaum cov yaj polymer ntws los ntawm cov txheej txheem spin pack, tiv thaiv tau tsim, kom cov yaj Friction generates tshav kub, kub nce, thiab rheological zog ntawm cov yaj yog zoo dua.Nyob rau tib lub sij hawm, lub yaj yog tag nrho tov los tiv thaiv viscosity sib txawv ntawm cov melts;cov yaj yog sib npaug rau txhua qhov me me ntawm spinneret;Nrog rau qhov nce ntawm lub sij hawm siv ntawm spin pack lim, impurities nyob rau hauv lub mesh pob lim txheej yuav nce, thiab lub siab ntawm lub rooj sib txoos yuav maj mam nce.Lub siab nce ceev yog ceev, thiab lub neej kev pab cuam ntawm lub rooj sib txoos yog luv.Thaum lub rooj sib txoos nce mus rau qee qhov siab, nws yog ib qho tsim nyog los hloov lub rooj sib txoos hauv lub sijhawm, txwv tsis pub, lub twj tso kua mis ntsuas yog crushed, los yog spinneret yog deformed, los yog leakage tshwm sim.

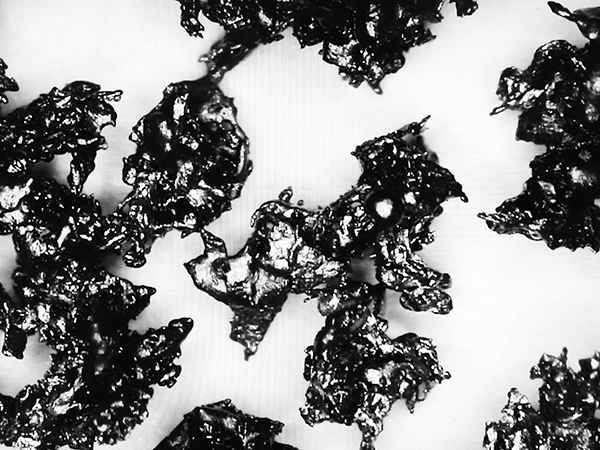

Kev xaiv cov khoom lim tsim nyog yog qhov tseem ceeb heev rau kev sib tw, thiab cov khoom siv lim dej zoo tshaj plaws yog qhov tseem ceeb tshwj xeeb.Nyob rau hauv tus txheej txheem ntawm spinning txoj kev loj hlob, nws kuj yog tus txheej txheem ntawm kev nrhiav ib tug zoo tagnrho shear lim nruab nrab.Ntau cov ntaub ntawv lim dej muaj xws li hiav txwv xuab zeb, hlau shavings, iav hlaws, sintered ntxeem tau hlau daim hlau, thiab irregularly zoo li tus hlau hais.

Ntxiv nrog rau qhov pheej yig, qhov zoo tshaj plaws lim nruab nrab yuav tsum muaj thiab yuav tsum muaj cov porosity siab ntawm cov kev ntxhov siab uas tau ntsib thaum lub sij hawm yaj polymer pom.Txhawm rau kom muaj qhov porosity siab, ib lub txaj ntawm cov khoom ntawm cov polymers kub feem ntau yog ib qho kev nyiam rau cov gel uas khaws cia rau hauv thiab txo cov kev ua haujlwm ntawm cov lim tawm.Yog li, cov khoom siv hlau lim dej yuav tsum tsis txhob catalyze lossis lwm yam ua rau kev tsim gel.

Nws muaj ntau dua kom tau txais cov xuab zeb hauv hiav txwv, tab sis nws yog qhov nkig heev nrog qhov tshwm sim uas qhov kev loj hlob ntawm cov khoom zoo zoo li cuam tshuam cov capillaries hauv spinnerets.Tsis tas li ntawd, qhov tshwj xeeb thaj chaw ntawm hiav txwv xuab zeb yog qhov tsawg thiab tsawg feem pua ntawm cov porosity rau ib qho twg muab ntim lim ntim, yog li lub pob siab yuav tsum nce siab.Stainless hlau hmoov uas tau npaj nyob rau hauv tej yam kev mob muaj ib tug tsis tshua muaj tshwm sim nto uas raws li tsis tshua muaj pom meej ntom, nyhav los txhim kho nws pom efficiency;Nyob rau hauv kev ua haujlwm pressures, nws ua kom nruj me ntsis thiab txhim kho kom muaj kev tshuaj ntsuam kom haum nrog me me los yog vau.

Post lub sij hawm: Aug-29-2018